Applicatio: Late adhibita in motore Brushless, Magnete permanenti motore industriae, motore textili, motore autocineto, magnete permanenti directo motore, motore lineari, aere condicioni motore compressore, instrumento mechanico motore permanenti, marino generante, magnete permanenti generante, magnete permanenti propulsu motore. fodienda magnete permanenti, motore coitu, motore chemico magnete permanenti, motore EV, motore sentino, EPS motore, sensori et aliis areae.

Product nativus: magnes omnes nativus, longitudo potest esse ab 0.5mm-200mm, latitudo ab 0.5mm-150mm, crassitudo ab 0.5mm-70mm, quod maxime postulationem clientium occurrere potest.

Coing: NdfeB magnes oxidize facile est, ita normaliter tunica opus est, litura communi in foro similis usus est;

1. ZN plating (quadam metalli vestis, salis imbre test 24-48 horas attingere potest, summa operandi sumptus est, ut in plerisque clientibus optima electio est).

2. NICUNI (quaedam metallica efficiens, salis imbre experimentum 48-72 horarum attingere potest, sumptus effectus altior est quam ZN, sed tamen valde late in foro conventus conditio dura est, producto corrosio resistendi requisita emptoris potest. eligere).

3. Epoxy (conductio non-metallica, conductivity non magnetica, potest reducere damnum currentis torrens motoris, probatio salis imbre 72-96 horas attingere potest, altior sumptus quam ZN NICUNI efficiens).

4. Alia vestis quae etiam usus est: Phosphate, Sn, Au, Ag, Parylene et cetera.

Tolerantia: Communiter magnes noster tolerantia +/-0.05mm post coatingit.

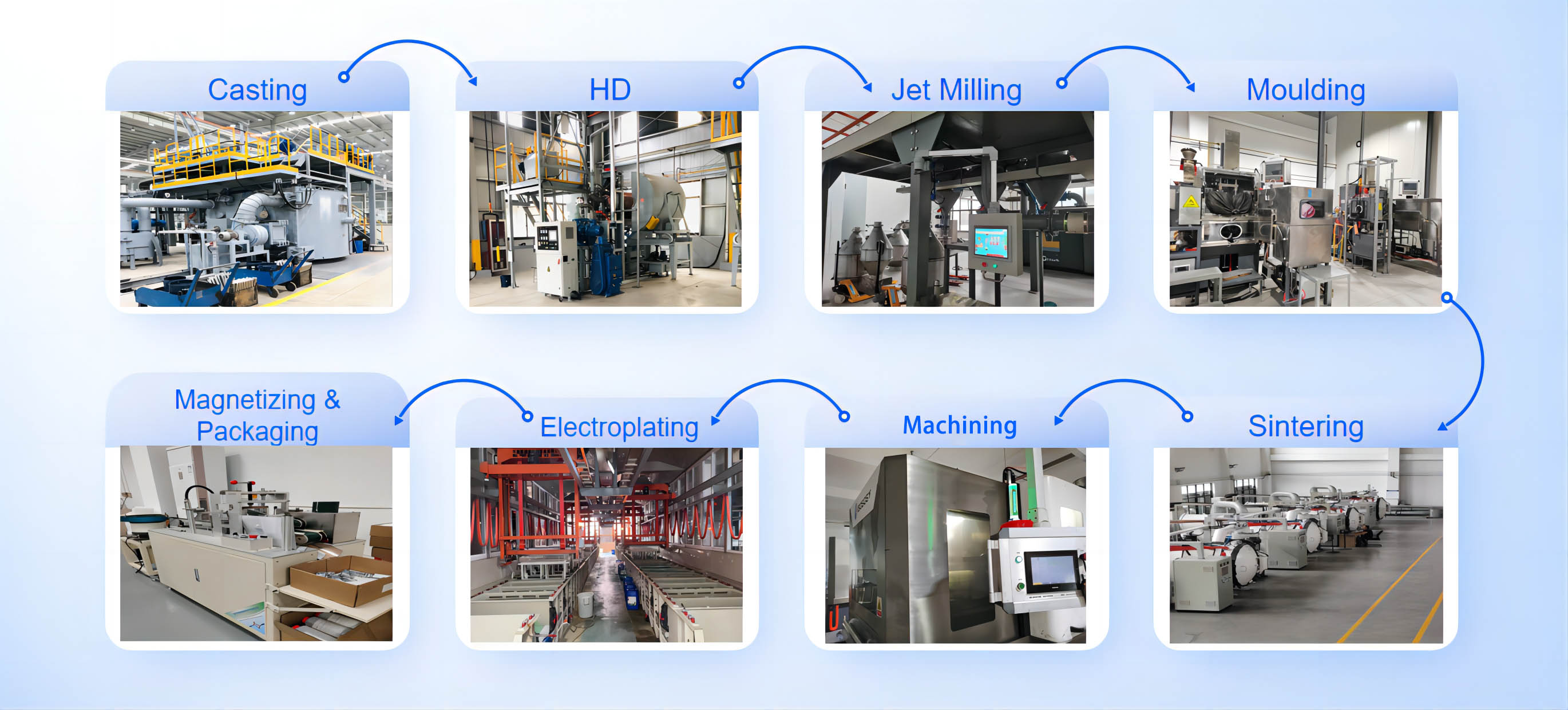

NdFeB Processus Productio

Introductio coating

| Superficies | Coating | Crassitudo μm | Color | SST Horae | PCT Horae | |

| Nickel | Ni | 10~20 | Clara Silver | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Nigrum Nickel | Ni+Cu+Ni | 10~20 | Clara Niger | >48~96 | >48 | |

| Cr3+Zinc | Zn C-Zn | 5~8 | Bright Blue Lucens Color | >16~48 >36~72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10~25 | Argenti | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Aurum | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10~ 15 | Argenti | >12 | >48 | |

| Epoxy | Epoxy | 10~20 | Nigrum / Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15~30 | >72~108 | --- | |||

| Zn+Epoxy | 15~25 | >72~108 | --- | |||

| passionem | --- | 1~3 | Griseo | Tempus Praesidium | --- | |

| Phosphate | --- | 1~3 | Griseo | Tempus Praesidium) | --- | |

Characteres corporei

| Item | Morbi laoreet | Reference Precium | Unitas |

| Auxiliaris Magnetic Properties | Reversible Temperature Coefficiens Of Br | -0.08--0.12 | %/ |

| Reversible Temperature Coefficiens Of Hcj | -0.42~-0.70 | %/ | |

| Imprimis Caloris | 0.104 | KJ·(Kg·℃)-1 | |

| Curie Temperature | 310~ 380 | ℃ | |

| Mechanica Physica Properties | Density | 7.5~7.80 | g/cm*3 |

| Vickers duritia | 650 | Hv | |

| Electrical Resistentia | 1.4x10-6 | μQ ·m | |

| Compressive fortitudo | 1050 | MPa | |

| Distrahentes fortitudo | 80 | Mpa | |

| inflexio robur | 290 | Mpa | |

| Scelerisque conductivity | 6~8.95 | W/m ·K | |

| Modulus | 160 | GPa | |

| Scelerisque Expansion (C⊥) | -1.5 | 10-6/℃-1 | |

| Scelerisque Expansion (CII) | 6.5 | 10-6/℃-1 |

Picture Display